FF Series (412FF/414FF/417FF)

페이지 정보

본문

|

|

|

|

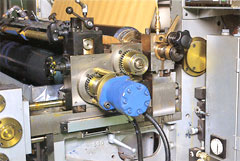

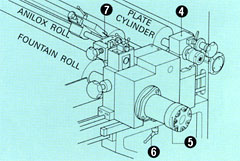

| NEW LONG presents the stack type flexographic printing press developed through the latest electronics and precision technology after long term experiences supplying more than 1,000 machines both of C.I.type and stack type into printing industry. |

|

|

|

||

|

|

||

|

|

||||||||||||||||

|

|

||||||

|

|

||

|

|

412FF |

414FF |

417FF |

|

Max.web width |

1,250mm |

1,450mm |

1,700mm |

Max.printing

width |

1,200mm |

1,400mm |

1,650mm |

Printing

length(10mm pitch) |

300-750mm |

300-750mm |

400-960mm |

Max.printing speed |

200m/min.

|

||

Number of colour |

4 |

||

Max.web diameter(unwinder) |

1,200mm(depending on printing materials)

|

||

Max.web diameter(rewinder) |

1,200mm(depending on printing materials)

|

||

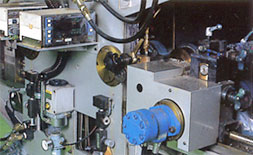

Drying system |

electricity,gas,steam

|

||

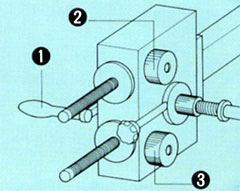

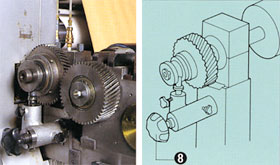

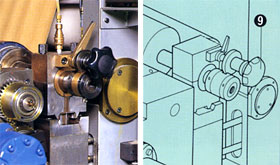

lnking system |

two rolls or doctor blade(*doctor

chamber)

|

||

Printing materials |

Paper 50-120g/㎡ PE PP 20-80× thickness

film |

||

Dimensions Standard machine The machine with varnish coating device |

L×H×W 9,500×4,500×4,500 11,300×4,500×4,500 |

L×H×W 9,500×4,500×4,700 11,300×4,500×4,700 |

L×H×W 9,700×4,500×5,000 11,500×4,500×5,000 |

|

||

서울시 강동구 풍성로 237 (둔촌동 518-5, 신라빌딩) Tel: 02-489-1953~5, 1934~7 Fax: 02-489-2152 Mail: silla@newlong.co.kr

서울시 강동구 풍성로 237 (둔촌동 518-5, 신라빌딩) Tel: 02-489-1953~5, 1934~7 Fax: 02-489-2152 Mail: silla@newlong.co.kr