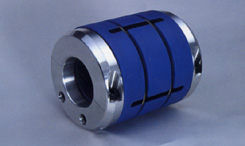

AIR SHAFT

페이지 정보

본문

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| NEWLONG Airshaft Dimensions |

|

|

|

|

| * We can manufacture airshafts of virtually any

size and specifications on request. * We also supply: ● Rubbertube ● Air gun ● Valve port ● Air gauge ● Gear (including collar) |

|

|

Type |

Cross Section | Structure | Features |

TUBE PT |

|

The lugs are held within the sahft O.D. by springs for easy insetion of the shaft into the web core. When air is injected, the rubber tube expands and the lugs are held firmly against the web core. |

|

SCREW TYPE PS |

|

The lugs move as you move the slope

core using the screw mechanism built into the journal shaft. The

lugs are pushed to hold the web core as the slope core advances

by turning the screw forwad with an impact wrench. The lugs return

when the screw is turned in the reverse direction. The lugs are screwd on to the shaft for easy replacement. |

|

CYLINDER TYPE PC |

|

This is the same mechanism as the above

screw type, but instead of the screw, air is injected to move the

piston. The lugs return smoothly by the spring built into the journal shaft on the opposite side as you press the suction valve. |

|

서울시 강동구 풍성로 237 (둔촌동 518-5, 신라빌딩) Tel: 02-489-1953~5, 1934~7 Fax: 02-489-2152 Mail: silla@newlong.co.kr

서울시 강동구 풍성로 237 (둔촌동 518-5, 신라빌딩) Tel: 02-489-1953~5, 1934~7 Fax: 02-489-2152 Mail: silla@newlong.co.kr